The aim of the pocket ventilation system is to optimize the drying process and machine runnability, and to avoid web fluttering and wrinkles. The innovative configuration and engineering of the enclosed hood allows us to supply the air along the production line both from front and/or the drive side.

Thanks to special blowing boxes, we can guarantee an even air distribution and control air humidity inside drying pocket.

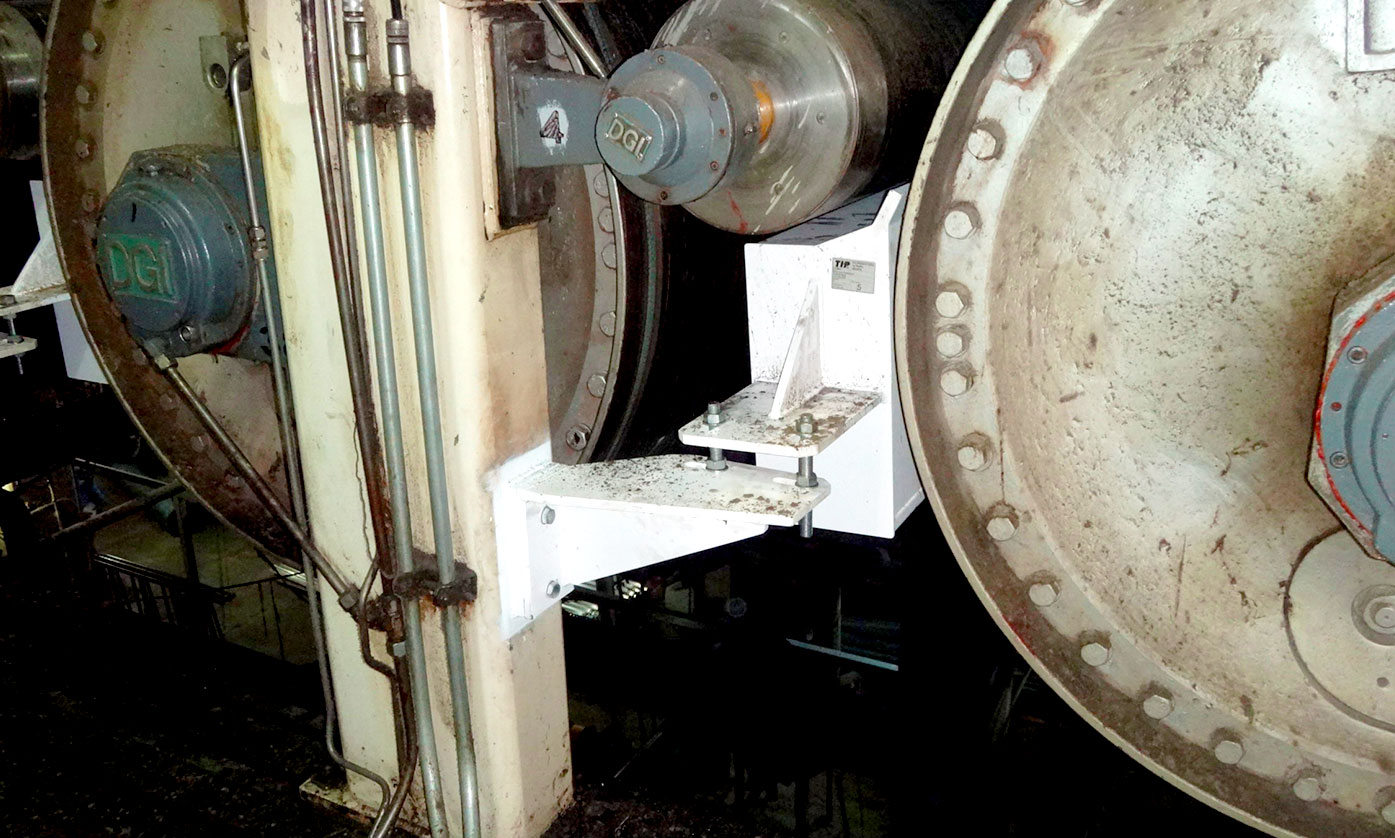

Blow boxes are installed on specific position inside machine:

- blowing boxes in unorun configuration (slalom groups)

- blowing boxes at central positioned felt rolls in double felted groups

- blowing boxes at felt rolls tangent on paper (touching the paper) in double felted groupd

- blowing boxes for bottom and top felt

- air knives at hood paper inlet and exit